When the 737-MAX was grounded in mid-march nobody would have imagined that the bird would be grounded for so long. But as MAX moves into the 4th month of its grounding shattering the previous record held by its cousin the 787 (January 17, 2013, to April 26, 2013) it is now 2nd only to Concorde in terms of the longest grounding for any modern airliner. With speculations about the future of the 737 getting out of hand and Boeing finally accepting its fault, let us take a step back and try to understand the lax in MAX.

History

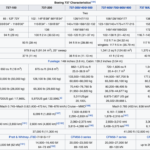

In order to truly understand MAX, we need to connect to its ancestors and start from the beginning. The 737 despite what Boeing might say is an ancient aircraft, derived from an even older 707 and 727. Since its 1st flight in April of 1967 Boeing has produced over 10,000 of these aircrafts, spread across 4 variants: 737, 737-Classic, 737-NextGeneration & 737-MAX and has orders for more than 4000 in its books. The variants though more efficient and larger than their predecessor, were just a mix of updates on ancient architecture and some genius level patchwork by Boeing engineers. For example, if you take a look at the images below, you can clearly see that the 737, which was originally designed for a turbojet engine now accommodates a high bypass turbofan, this caused severe ground clearance issues for the engine and resulted in the iconic hamster mouth design of the engine inlet by shifting all the auxiliary components of the engine components from directly below to towards the side of the engine. A deeper look into the character sheet of the 737 also reveals that they are not just different variants but they are completely different aircraft. With the MAX producing twice as much thrust as the original 737 and carrying nearly double passengers as well, one can not help but wonder how is it the same aircraft? Unfortunately, to bring training & re-certification cost down and retain/gain customers Boeing decided to brand them all as the same aircraft. Something which has now become a scaringly common practice, take the F-35 A/B/C for example 3 entirely different aircraft with a completely different role bundled up together in the name of reducing cost and we all know what came out of it but that’s a story for another day.

The Modification and The Crash

Now one of the key modifications in the MAX, as compared to the Classic and the Next generation, is the higher bypass turbofan engine. From a bypass ratio (BPR) of 5.5-6 and fan diameter of 60-61 inches in the CFM 3 and 7 series to a new CFM leap 1B engine with a BPR of 9 and a fan diameter of 69.4 inches. But this isn’t the 1st time they have put in a larger engine, but then it is also not the 1st time they have had 2 back to back incidents because of engine problems, post-modification (I know you want to blame the MCAS for it, but the MCAS exists only because of the problems that the engine created). Introducing the 1st leap from 737 to 737-Classic from a turbojet to turbofan from 50 inches to 60 inches in fan diameter, what happened? well open google and search 737 crash or just click here.

Incidence 1: TACA Flight 110, en route to New Orleans, suffered double engine failure due to a severe hail storm. Fortunately, no one died but ss a result of this incident, further engine development was carried out to prevent flame-out in severe weather conditions.

Incidence 2: Kegworth air disaster: British Midland Flight 92, using a 737-400, crashed outside of East Midlands Airport. Of the eight crew and 118 passengers, 47 passengers died. The left engine had suffered a fan blade fracture and the crew, unfamiliar with the 737-400, shut down the still-functional right engine, causing the aircraft to lose power.

Boeing along with the agencies responsible for ensuring the safety of our skies blamed the pilots and dismissed them. But guess what while the pilots did commit some mistakes, no one bothered to ask why they committed them? Why they were so unfamiliar with the aircraft they were flying? is it because they did not have enough training? is it because someone making those planes said they would not need extra training? We might never know, but what we do know is that after the investigation and dismissal, the British Midland paid the first officer, McClelland of that fight an out-of-court settlement for unfair dismissal and the captain of the flight in April 1991 told a BBC documentary: “We were the easy option—the cheap option if you wish.” Does this ring a bell, remember who was blamed initially for the MAX crashes? Is it history repeating itself? or is it BOOOEING repeating its mistakes? Judge for yourself.

The Present Situation

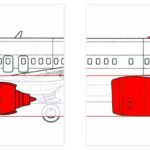

Now we fast forward to the 21st century, and contrary to what you might think “size does matter” especially if it’s the size of your turbofan engine we are talking about. You see back in the days 737 was pretty much without a good rival, then came the A-320 a modern airliner designed to operate with a High BPR turbofan engine and guess what it started to cut into the 737s market. The rivalry was going well, till that day in September 2014 when the A320 NEO (New Engine Option) with its massive CFM Leap 1A engine having a BPR of 11 and a fan diameter of 78 inches, took its first flight. Promising amazing fuel efficiency and longer range, the A320 NEO raked up orders in the thousands and split the market into 2 equal halves where the 737 was an uncrowned king. How did Boeing react? They MAXed out the 737 (perhaps the name itself holds a cryptic message by the engineers at Boeing warning its management that this platform has now reached its maximum utility) forcing it into its 1st flight on a cold rainy day(official Boeing description of that day at 0:13 seconds) just 4 days after the A320 NEO was introduced into service by Lufthansa. Boeing tried to put the same CFM Leap engine in the MAX but was reluctant to redesign and recertify the aircraft, they slightly modified the engine (made it smaller, BPR of 9 and fan diameter of 69.4 inches) called it CFM Leap1B. But then the 737 NGs were already short on ground clearance, how did Boeing Sqeze in the extra 10 inches? Well like I said, a mix of updates on ancient architecture and some genius level patchwork by Boeing engineers. They increased the main landing gear height by 6 inches pushing it to the MAX without redesigning the entire landing gear bay (& possibly the fuselage section), placed the engine to the MAX possible forward and top location in front of the wing, did some modification on the nacelle threw in a vortex generator and voila problem solved or maybe not.

The MAX crash

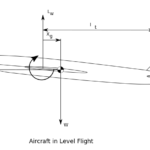

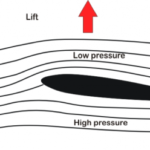

So how did the last 2 MAX crash? Popular media says its the fault of the Maneuvering Characteristic Augmentation System (MCAS), but then the MCAS was snuck into the aircraft (Quite literally many pilots weren’t even aware of its existence till the 1st MAX crashed) to solve the problems caused by the new engine not amplify it. The hardware problem that this software patch was trying to fix was that the pitch up tendency of the 737 MAX during takeoff (High thrust and high AoA condition). Why did MAX have this problem, because of the law of longitudinal stability of an aircraft, the further away from the aerodynamic center is from the CG the greater pitch up tendency an aircraft would have and the more pitch unstable it becomes. In the overlap below you can see that the MAX has a lit bit extra nacelle pooping out in front, at cruise conditions the nacelle is designed not to produce any lift but at high AoA the Nacelle also starts to produce lift moving the Lw a bit more forward of the CG. Now, couple this with the higher engine location and uses the knowledge of how lift is produced (Higher pressure low-speed air under the wing and low-pressure high speed over it) and you see hot high-speed air blowing right underneath the wing and we have a recipe for disaster.

The MCAS was put in to apply a pitch down moment by trimming the horizontal stabilizer, increasing Lt value and for the MCAS to activate, the following must be true:

- The Angle of Attack (AoA) as read by the sensor exceeds a specific parameter (specifically, the sensor shows a high AoA which means that the aircraft is approaching a stall condition)

- The flaps are fully retracted (which means that the aircraft is not/is no longer in take-off or landing configuration)

- The aircraft is being flown manually (the autopilot is not engaged)

If these three things are true, then the MCAS will trim the aircraft stabilizer nose down and stabilize the aircraft. Now, there are numerous theories on how tracking data from a single faulty AoA sensor to the MCAS resulted in the crash. Because if the MCAS has been reset (for example by a manual trim command) then if the AoA is still high after five seconds without pilot trim command, it will activate again. The MCAS can and will continue to pitch the nose down in up to 2.5° increments if the high AoA reading has not been resolved. In this way, it is possible for the stabilizer to reach the nose down limit, pitching the aircraft down as steeply as it can [1]. Which is in fact what happened as both the crashes were caused by the aircraft steeply nose-diving into the ground.

But then let’s face facts if the issue was some faulty sensor package/software Boeing has enough smart engineers to resolve the issue in literally no time and a company like Boeing does not just give away $100 million as compensation to crash victims, which is excluding the backchannel compensations and discounts it is providing to all present and potential MAX operators. What has happened is something way more serious than that, its a culmination of years of corporate greed, weakening of regulatory bodies and poor design choices, unfortunately, made by some of my fellow engineers that have for the lack of better word resulted in this clusterfuck. Driving a star performer to the dogs, serving as a stark reminder to anyone trying to cut cost by compromising on design and certification cost. In Boeing’s defense, it has tried to come out clean in the past few months and given released some bold statement but we don’t expect a 103-year-old company to act like a 3-year-old. As an industry leader it would be nice to see Boeing not just compensating but also own up to its mistakes and tell everyone what actually went wrong so that we can all learn from it and young engineers like myself can once again proudly say:

“If it’s not Boeing, I am not Going.”

[1] Source

Nicely summarised, Jetboy. It’s a grim reminder that only so much can be extracted out of a legacy machine. In the blind race for orders and bottom lines, basic rules of the game in design, flight test and certification have been violated. Unfortunately in this game, lessons come at a huge price and this $100m dole may just be the tip of the iceberg, considering the loss of face, worldwide grounding and abject lack of a credible defence to the MAX saga from Boeing itself.

Hope no more bandaid fixes are used to prop up grandfather rights over a mountain of dead people.